|

Our client brought their vehicle to us to restore the paintwork, wheels, interior & exterior trims and underguards after purchase. Our client’s instructions were to restore this vehicle to as pristine condition as we could; factory fresh if possible. This is the type of challenge we relish!

|

| We firstly raised the vehicle and removed each of the wheels, then set them aside for individual detailing. Our pillarless hoist allows us to safely continue work on & around the vehicle while raised. and saves the time & potential risk involved when manually jacking a car to put on axle stands. We use a special wheel bolt socket extension with plastic caps to remove and refit wheel bolts & nuts. This ensures no scratching occurs on the surface of wheel in the process. | |

Whilst the wheels may have looked ok at first glance, closer inspection showed quite a lot of marks and grime attached to the spokes & barrels. This is indicative of brake dust & contamination that needs to be removed.

| The inner barrels are an area that makes so much difference to the look & general cleanliness of a vehicle. Whilst we thoroughly detail the inner wheel barrels in each of our detailing stage packages, the absolute best way to remove all dirt, grime & contamination is to remove the wheel. This gives us a much greater working area, and we can achieve a much better result. Even though this Ferrari is seldom driven, we found traces of tar, iron from brake dust and mud on the inner barrel of one wheel alone! Using our safe techniques & products, we decontaminated each wheel individually. A combination of our safe pH-neutral Dragon’s Breath wheel cleaner, mild tar remover & soft boar’s hair brushes removed the majority of the contamination. After the brake dust and grime was cleansed from the faces and barrels of each wheel, we brought them inside to remove the tar. We used a light tar remover to safely lift the tar residue from the wheel surface, removing the need to perform any heavy scrubbing & in turn further damage the wheel surface. Safety is paramount in our ethos at OCD, and flows throughout all we do. | |

| Once the wheels were fully cleaned & all contamination was removed, we applied a synthetic wax to help repel contamination, add protection & increase the shine. Our wax also helps repel water, as evident in the beading water on the surface of the center cap, wheel barrel and wheel face. | |

Comparing before & after shots of the wheels clearly shows the difference having a cleaned, decontaminated and protected wheel face & barrel makes!

Part Two: Underguard Detail

| With the wheels detailed & protected, we now moved our focus to the underguards. Initial inspection indicated dirt & grime covering the underbody, plastic guard trim, brake calipers & suspension components. Our goal for this process was to remove the dirt and contamination from the underguard and components, and protect each item individually. | |

| As with the wheel detailing, the first step was a comprehensive decontamination of the underguards. We started with the plastic liners, using a degreaser & brush to remove the tar & dirt from the surfaces. We scrubbed each underguard to remove the heavier contamination. The brake calipers were also detailed to remove the iron brake dust from the pads. To follow up the decontamination we hand-polish each painted caliper to restore colour & bring up the shine. | |

| With each component cleaned & detailed we moved to the protection step. Underguard protectant was applied on the plastics & suspension components, whereas wax was applied by hand to the painted calipers. | |

Cleaned & protected underguards.

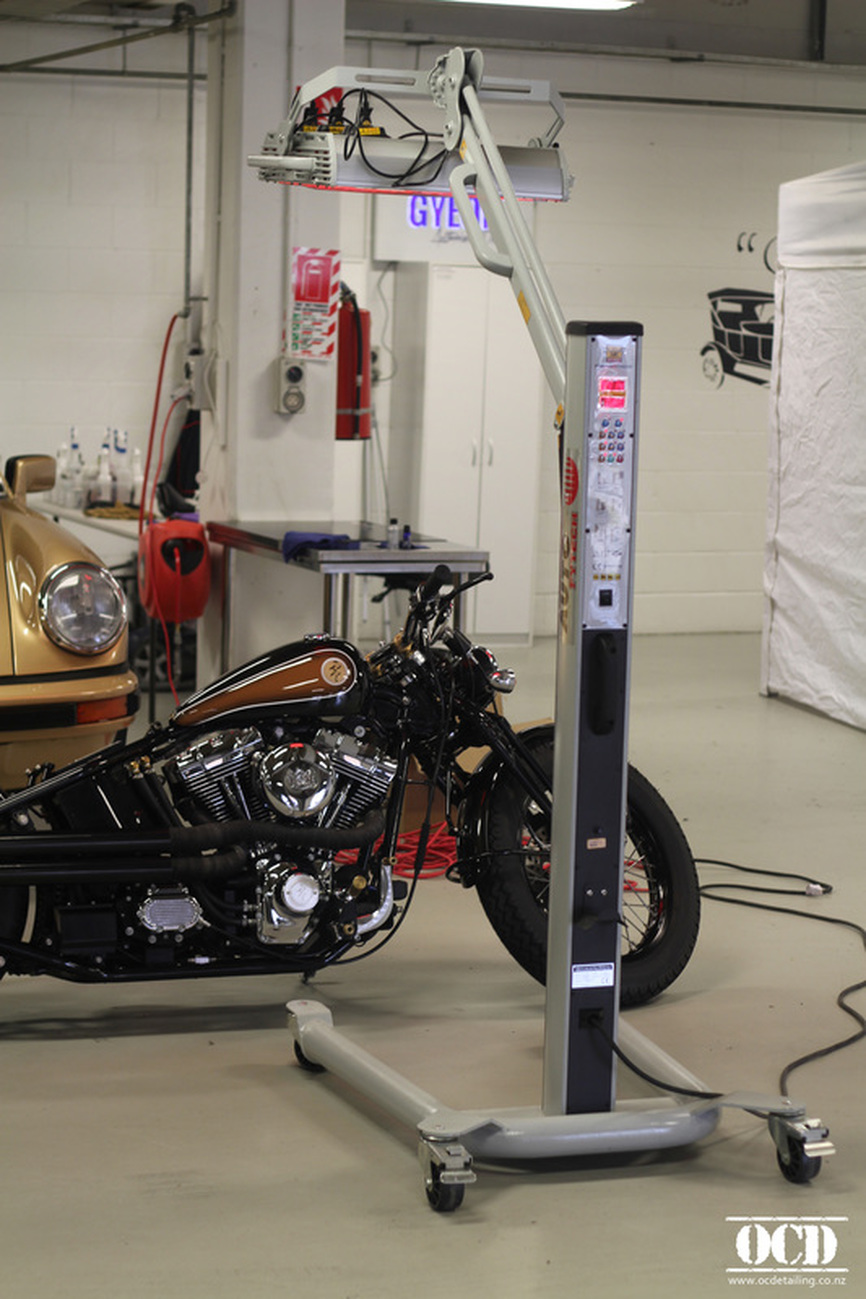

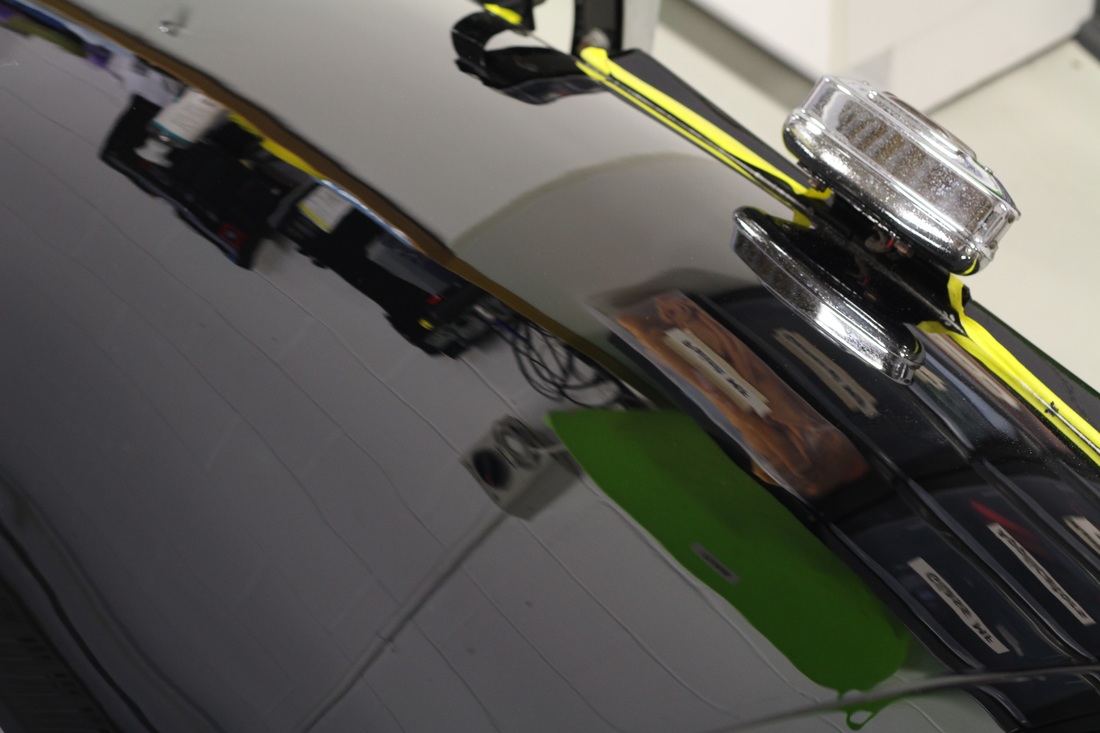

We were called upon to detail a recently acquired 2012 Lamborghini Gallardo Superleggera LP570-4. Painted in Verde Ithaca green and with plenty of carbon fiber accents this particular example stands out from the crowd; one of the big selling points for our customer. In his words he wouldn't have bought any other colour.

Upon an initial phone call it was clear this car was in fairly good condition; however we knew that there is always room to improve. Note this insight post is heavily image based and written to cover all points with a high level of detail. We highly recommend boiling the kettle and making yourself comfortable!

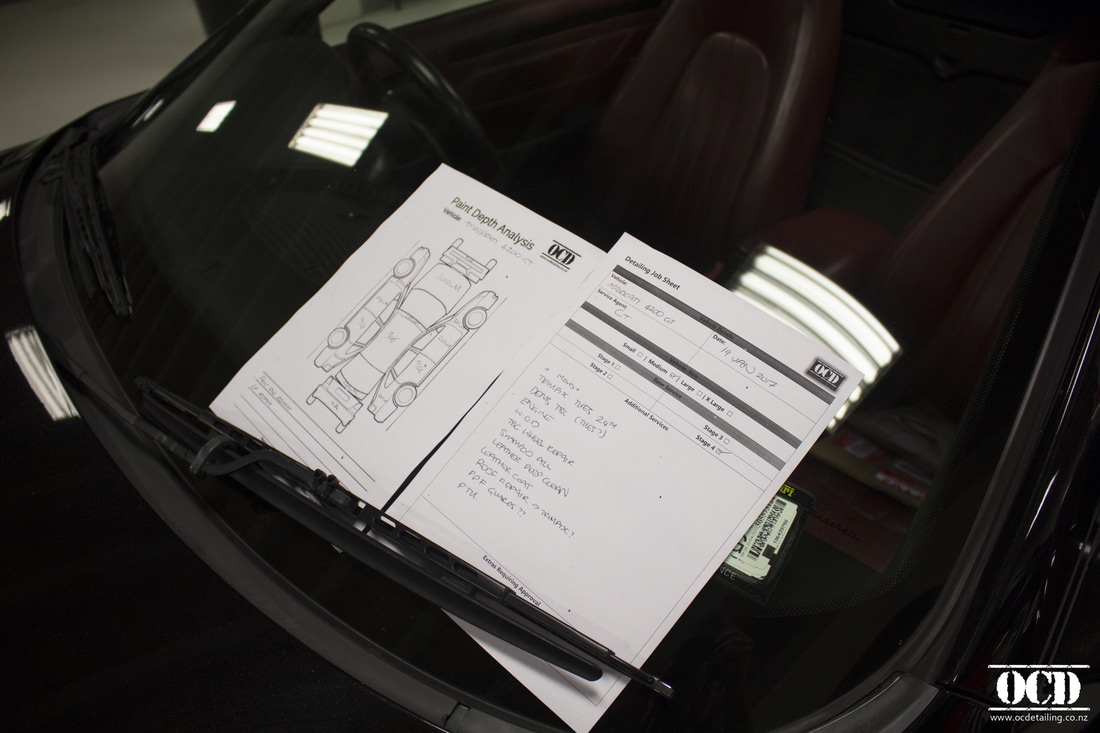

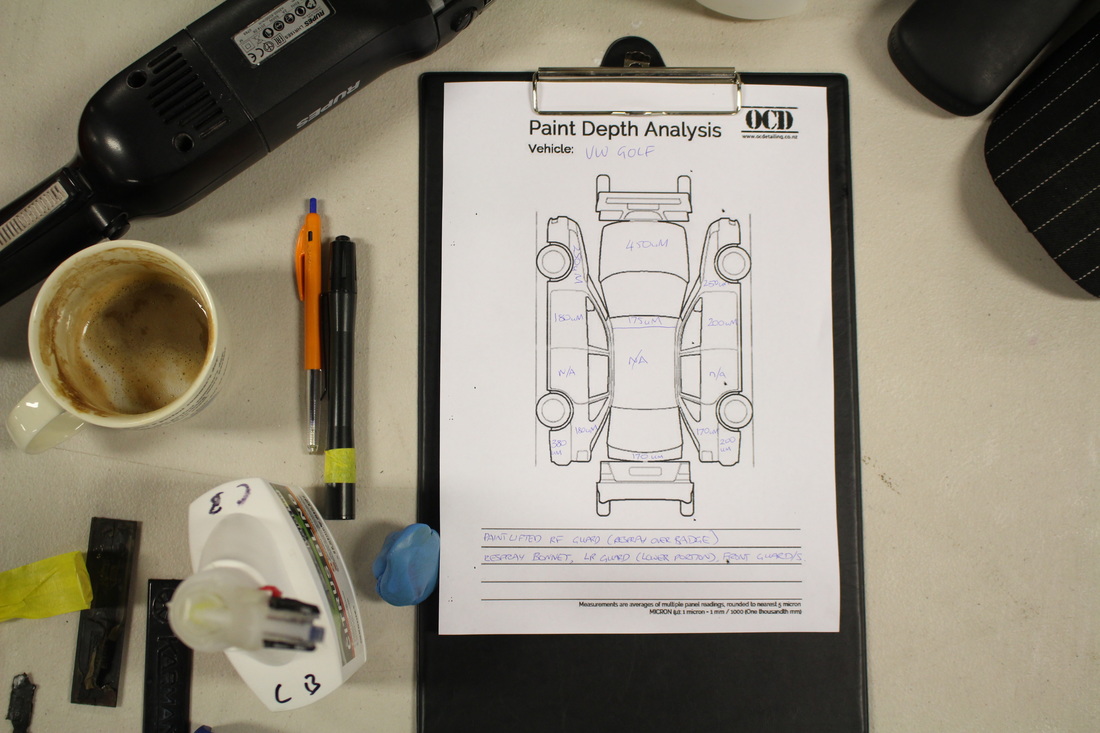

The initial plan of action was to inspect all areas of the vehicle with an idea to start with a Stage 4 Restoration Package plus add on a wheels off under guard detail, interior carbon fiber detailing and any other areas that needed addressing.

Upon an initial phone call it was clear this car was in fairly good condition; however we knew that there is always room to improve. Note this insight post is heavily image based and written to cover all points with a high level of detail. We highly recommend boiling the kettle and making yourself comfortable!

The initial plan of action was to inspect all areas of the vehicle with an idea to start with a Stage 4 Restoration Package plus add on a wheels off under guard detail, interior carbon fiber detailing and any other areas that needed addressing.

Initial Delivery & Inspection.

The photos below are of the vehicle as it was initially delivered to us. Our customer was kind enough to have washed the vehicle not long before delivery, and on the surface you would not consider this car to be heavily defected - in fact it almost looks brand new. This is one of the great challenges of detailing; taking a vehicle in already good condition and further improving it to better than factory finish. We love showing photos like this as it gives a true indication of how on the surface a car may look clean and tidy; but detailed it is not.

The photos below are of the vehicle as it was initially delivered to us. Our customer was kind enough to have washed the vehicle not long before delivery, and on the surface you would not consider this car to be heavily defected - in fact it almost looks brand new. This is one of the great challenges of detailing; taking a vehicle in already good condition and further improving it to better than factory finish. We love showing photos like this as it gives a true indication of how on the surface a car may look clean and tidy; but detailed it is not.

| Initial Wash Down Process The initial wash down process consists of 5 steps. 1) Wheel Decontamination is the initial step. We choose to decontaminate wheels first as it avoids the chances of re-soiling paintwork if dirt splashes from the wheels or tyres. Using a pH neutral, iron reacting wheel decontaminant we can liquefy the brake dust particles. In the photos below the purple trails represent the iron (brake dust) which has reacted with our specialist products. We allow the product to react and lightly agitate to loosen built up deposits from the wheel surface. As part of the wheel decontamination process we apply a mild degreaser to the tyres; leaving a clean surface for better bonding of tyre protectants. We also apply our secret wheel sealant at the same time; easing future maintenance by repelling dirt and water between cleans. 2) Under Guard Degrease & Rinse. We perform a light degreasing of the under guards to remove grease and road grime. In the example of this Lamborghini we are completing a wheels off detail in our studio and so this step is mainly to remove the heavier grit from under the guards, not focus on removing all dirt at this stage. 3) After treating the dirtiest areas on the vehicle we begin with Snow Foam Pre-Wash treatment to loosen top surface dirt and grit from all the exterior surfaces of the vehicle. A snow foam pre-wash is not often seen in the New Zealand market but plays a crucial part in a quality car care regime. By loosening and pressure washing off the top layer dirt you are leaving a far cleaner surface to work with before any touching of the vehicles surfaces begins. The overall purpose is to not only clean hard to reach areas but heavily reduce the risk of inflicting nasty swirls and scratches into the paintwork. As can be seen in the photos here, snow foam also helps to remove any wheel cleaner that may be trapped around wheel nuts and other tight areas. 4) A Two-Bucket Method Wash is now completed as the vehicles exterior surfaces have now been prepared for washing. The two-bucket method is widely used by professional detailers and hobbyists alike as a safer way to wash your vehicle. The way we describe it to many customers is that when using only one bucket you are essentially transferring the grit from each panel of your car to the next - in turn causing swirl marks and generally damaging the paint surface. With a two-bucket method the wash mitt is constantly rinsed to allow clean soapy water to contact the paintwork. You can see in the photos two buckets; one with our car shampoo and one with clean water to rinse. We use lambswool wash mitts for a safe and thorough wash. Two different size mitts allow us to reach all areas of the vehicle thoroughly; as demonstrated by the photos. 5) Drying the vehicle safely is done with our Air Dryer. This imported machine pumps out a whopping amount of heated, filtered air to dry even the hardest areas to reach. This helps to prevent drips, water spots and is far more thorough than traditional towel drying. Each type of drying method has it's place - in this case we wanted the Lamborghini as dry as possible in all areas. | |

Inspecting For Defects

After the vehicle has been washed down, dried and is inside our studio we can really start to see what we're dealing with. When setting up our studio we were sure to choose the correct lighting with the right amount of Lumens for the level we are detailing cars at; something which we didn't have the luxury of at our previous Newmarket studio. The two main types of defects we will discuss are marring and scratches on both the painted surfaces, plastic lights and carbon fiber surfaces plus the contamination on the paintwork.

After the vehicle has been washed down, dried and is inside our studio we can really start to see what we're dealing with. When setting up our studio we were sure to choose the correct lighting with the right amount of Lumens for the level we are detailing cars at; something which we didn't have the luxury of at our previous Newmarket studio. The two main types of defects we will discuss are marring and scratches on both the painted surfaces, plastic lights and carbon fiber surfaces plus the contamination on the paintwork.

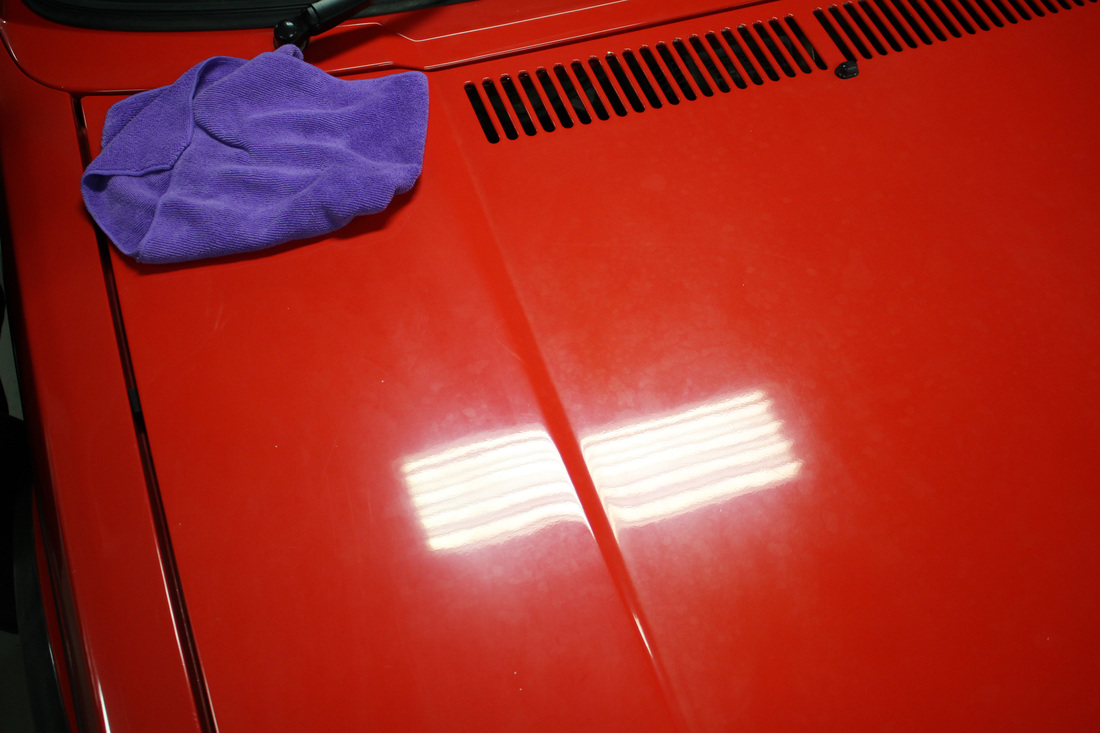

| Contamination Contamination is something not easily picked up by the naked eye. We worked hard to get these photos as they show in true form the contaminants on the paintwork. The type of contamination on this Lamborghini paintwork is mainly iron fallout and some tar around the rear of the vehicle. While this contamination may seem minor it could lead to problems further down the track as it tends to etch into the paintwork. Polishing a contaminated car can lead to poor results also, increasing the chance of marring the paintwork. Removal of these contaminants prior to polishing is covered in the next section. Paintwork Marring Using different types of Halogen & LED lighting we were able to observe marring across most of the painted surfaces of the vehicle. Light swirl marks are commonly caused by improper wash technique which is almost certainly the case with this vehicle. We were also able to observe buffer trails on some areas of the car, especially the front bumper. These buffer trails are caused by improper machine polishing - possibly by a previous detailer or the vehicle dealership. Marring on the paintwork is unsightly and also causes a hazy look to the painted surfaces. To achieve a true mirror finish we must remove the marring from the paint. Check out the slideshow to the right. You can see various different formations of swirl marks over most of the painted surfaces of the vehicle. Carbon Fibre Marring All modern cars with exterior carbon fibre have a clear coat layer similar to the vehicle paintwork; this means the carbon trims are susceptible to marring and swirls just like the paintwork. Marred carbon fibre appears dull and not deep and shiny - the carbon on this Lamborghini was in need of some help, as seen in the slides to the right. Taillight Defects The taillights on this Lamborghini are plastic and over time, just like paint, they will get marring and swirl marks. On a plastic surface this makes the lights appear duller and not as deep and red as they should appear. These Lamborghini taillights are quite obviously defected as shown in the photos. Luckily we can fix this with a combination of different polished to restore an as-new appearance to the lights. Headlight Defects The headlights are generally made of a harder and more resilient plastic vs the taillights. You can see in this example while there are some light marks and marring on the headlights themselves, it is the small black piano inserts which are very obviously covered in fine swirl marks. Black piano trims, like black paint, show all defects but present a lovely finish when they are properly polished. | |

Attacking Dirty Areas First

It is always good practice to attack the dirty areas of the car first - in this case the wheels and under guards. As we are removing heavy grime from these surfaces we want to ensure that there is no chance of re-contaminating paintwork or having any splashes or grime hit the paintwork. If grime does get re-introduced to paintwork we would prefer that happens before we have spent countless hours polishing to perfection!

It is always good practice to attack the dirty areas of the car first - in this case the wheels and under guards. As we are removing heavy grime from these surfaces we want to ensure that there is no chance of re-contaminating paintwork or having any splashes or grime hit the paintwork. If grime does get re-introduced to paintwork we would prefer that happens before we have spent countless hours polishing to perfection!

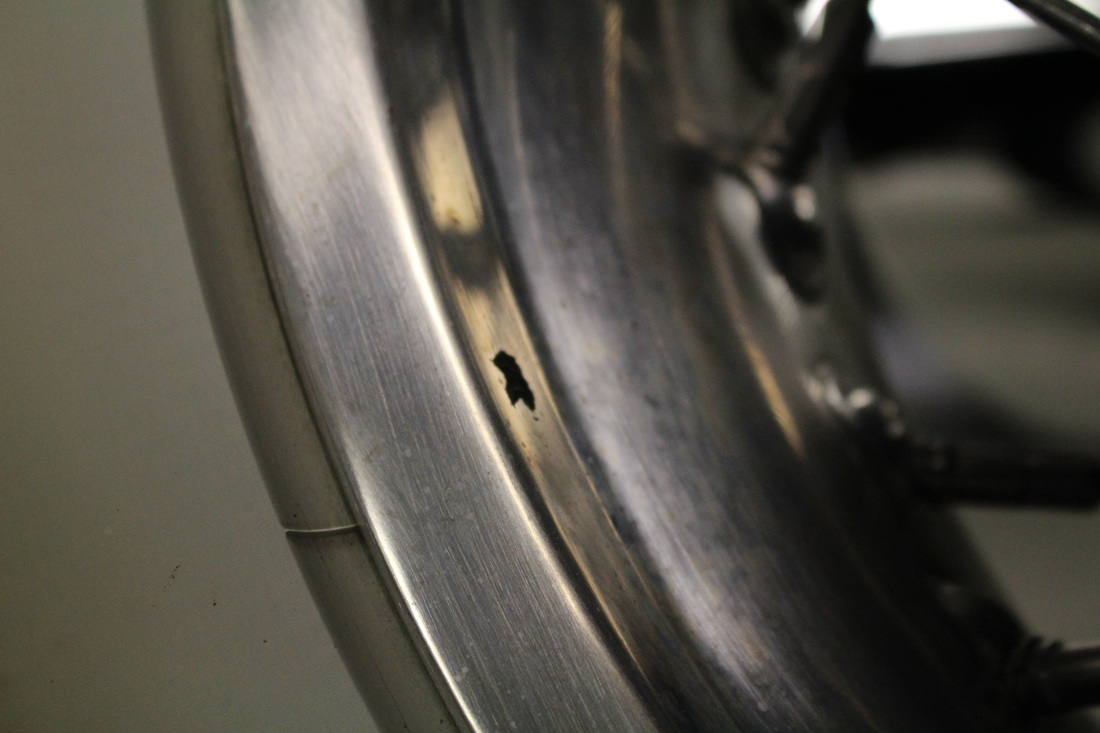

| Wheels After the wheels were removed from the wheel we began to inspect for defects. It was instantly apparent that not only was there tar and iron from brake dust but also three of the four wheels appeared to have some form of over-spray on the inner barrels where the wheel was matte instead of glossy. This is common to see on 'cheap' wheel repairs - quite a shock for a car of this calibre. We started by removing the tar and attempted a cut and polish process to remove the heavy over-spray (as seen in the pictures). It was decided the process was too risky and that these wheels deserved to be done right. The text on the outside of the wheel was also shallow due to being filled with excessive amounts of paint; so this would also need to be addressed. We sent the wheels away to Arrow Wheels - who we regard as the best in the industry. After a few weeks of intensive stripping and repainting the end result was here - amazingly these looked brand new and the now OEM glossy paintwork matched the superior gloss to the Verde Ithica paintwork. | |

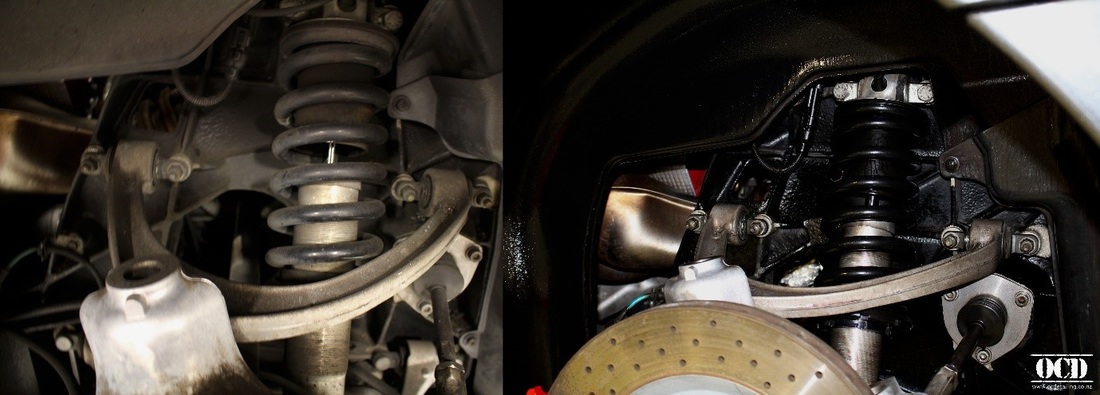

| Under Guards The under guards are one of our secrets here at OCD. A true wheels off detail will take a seemingly clean car to the next level of clean! Removal of grime, oil, grease, brake dust and tar takes time but is worth the result. We start off by removing all the wheels from the vehicle. We then place down drop sheets to catch the mess from the under guards (not seen in these photos). Using both citrus degreaser plus tar remover we get to work scrubbing all the plastics, suspension components and painted surfaces as thoroughly as we can to remove dirt and debris. After allowing the surfaces to soak thoroughly we rinse off all of the grime and inspect for any required follow up or re-treatment. As a final step we dry all the surfaces and protect the plastics and paint where possible plus hand polish and seal the brake calipers too. The 50/50 shot doesn't lie - just look at that result! | |

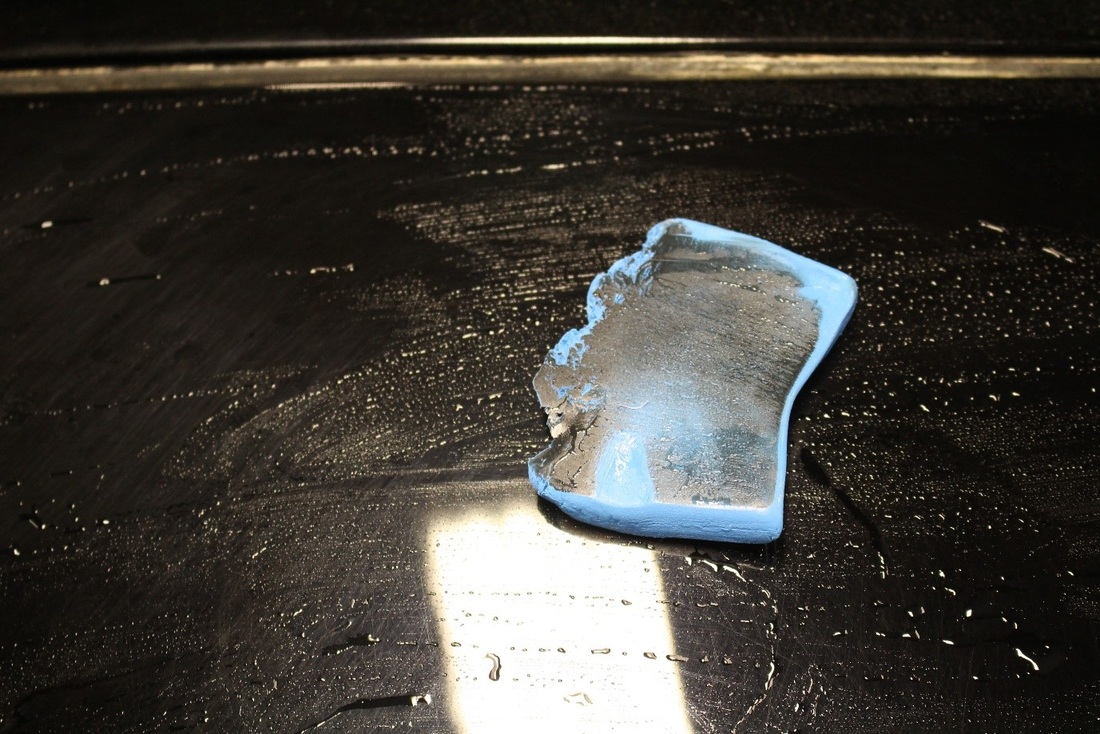

| Decontamination We are now ready to prepare the exterior surfaces for correction. With our Stage 4 package we clay bar the paintwork, the glass and the plastic lights front and rear to remove as much of the surface contaminants as possible. For this particular car we chose to use a mild clay bar as the contamination is not too severe and there is far less chance of causing any additional clay marring. These pictures of the clay bar show just how bad the bonnet really is. Mild clay bars start as a clean, bright yellow colour - and quite easily show what is being removed off the paintwork. When decontaminating we continue working the surfaces until they are completely smooth and contamination free. It is a common misconception that polishing a car smooths out the surface; really a properly decontaminated car should be as smooth as a polished car would ever be! | |

Paint Correction

OCD specialise in paint correction and this Lamborghini was no exception. The customer had one request; to bring the paintwork to the best possible level. We operate to achieve two main objectives; removal of as many of the swirl marks and scratches as we can safely remove plus produce the best level of depth and overall shine. To achieve this we performed a two stage compound and polish on the paintwork.

Compounding

Compounding is the process of leveling the paint surface to remove scratches, swirl marks, buffer haze and other top layer defects. The compounding process increases shine to the paintwork but does not produce THE BEST shine possible. It is common of some operators to simply compound the paintwork and not follow up with a secondary process; we however do not cut corners!

Polishing

In this instance we used a fine finishing/jeweling polish to remove fine haze left by compounding and jewel the paint surface to a level of clarity not often seen in the New Zealand detailing scene. This is truly one of our biggest differences and the products we use we import ourselves ex-Germany. After thorough testing of countless different products we have settled on the best.

Machines

We use dual action machines to achieve a crystal clear result and with maximum safety. Unlike traditional polishing machines, dual actions both spin and oscillate to ensure they are constantly moving across varying elliptical orbits. This reduces heat and in turn means less chance of burning paint, no chance of creating holograms and buffer marks and we wouldn't have it any other way. On top of this we have invested in multiple different sized machines to ensure we can correct varying surfaces and even complex panels with ease.

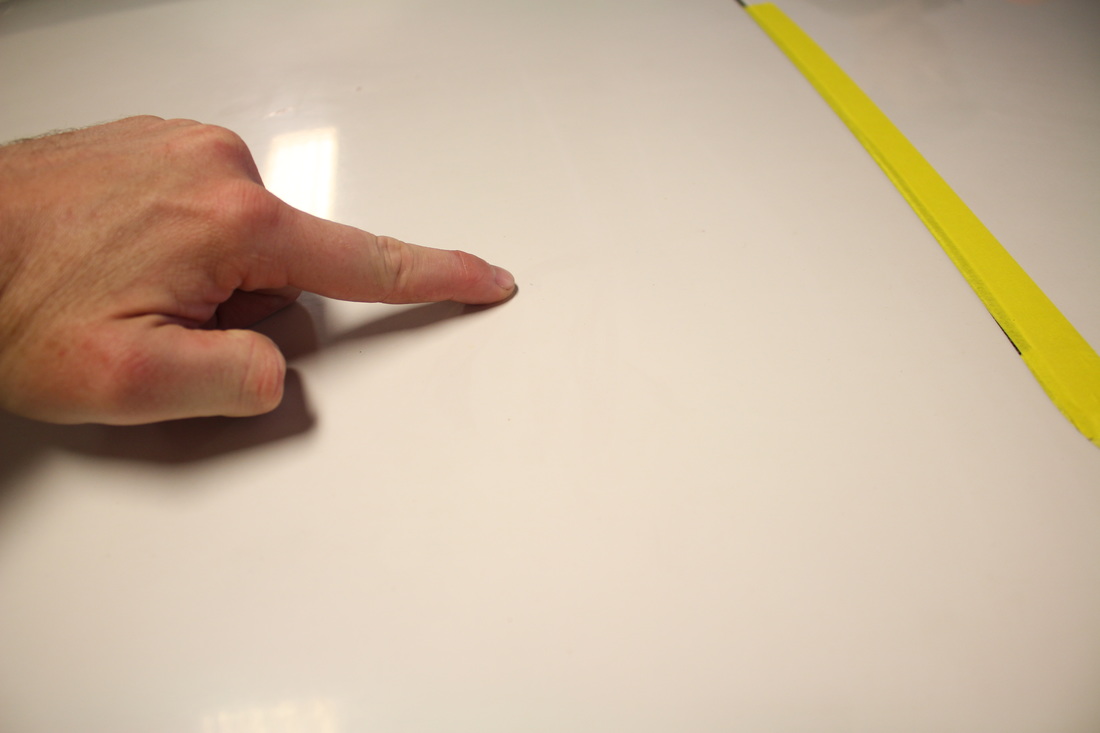

The below images are 50/50 shots of compounding in action. To achieve these shots we have taped off a line to make it easier to see the correction result. Look out for the swirls and where they suddenly disappear! This is the result of a true cut and polish - removal of defects, not polishing to add more like some inexperienced detailers will!

OCD specialise in paint correction and this Lamborghini was no exception. The customer had one request; to bring the paintwork to the best possible level. We operate to achieve two main objectives; removal of as many of the swirl marks and scratches as we can safely remove plus produce the best level of depth and overall shine. To achieve this we performed a two stage compound and polish on the paintwork.

Compounding

Compounding is the process of leveling the paint surface to remove scratches, swirl marks, buffer haze and other top layer defects. The compounding process increases shine to the paintwork but does not produce THE BEST shine possible. It is common of some operators to simply compound the paintwork and not follow up with a secondary process; we however do not cut corners!

Polishing

In this instance we used a fine finishing/jeweling polish to remove fine haze left by compounding and jewel the paint surface to a level of clarity not often seen in the New Zealand detailing scene. This is truly one of our biggest differences and the products we use we import ourselves ex-Germany. After thorough testing of countless different products we have settled on the best.

Machines

We use dual action machines to achieve a crystal clear result and with maximum safety. Unlike traditional polishing machines, dual actions both spin and oscillate to ensure they are constantly moving across varying elliptical orbits. This reduces heat and in turn means less chance of burning paint, no chance of creating holograms and buffer marks and we wouldn't have it any other way. On top of this we have invested in multiple different sized machines to ensure we can correct varying surfaces and even complex panels with ease.

The below images are 50/50 shots of compounding in action. To achieve these shots we have taped off a line to make it easier to see the correction result. Look out for the swirls and where they suddenly disappear! This is the result of a true cut and polish - removal of defects, not polishing to add more like some inexperienced detailers will!

Paint Correction 50/50 ShotsTail Light Polishing 50/50 Shots | Polishing In ActionAfter Paint Correction Is Completed |

Paint Sealing & Final Wax

After the vehicle has been fully corrected we perform a final wash down to remove all traces of dust from the vehicle, and prepare the surface for the final stages of protection and enhancement. On all Stage 4 packages we complete a two-step final including both a synthetic sealant and also a carnauba wax.

After the vehicle has been fully corrected we perform a final wash down to remove all traces of dust from the vehicle, and prepare the surface for the final stages of protection and enhancement. On all Stage 4 packages we complete a two-step final including both a synthetic sealant and also a carnauba wax.

| Paint Sealant A synthetic sealant is a man made product designed with three main aspects in mind. Protection - to help repel dust, dirt and water plus provide a resistance towards bird droppings, in-air contaminants and mineral deposits. Increased Shine - adding a sealant layer increase shine, depth and gloss of any paintwork colour. This further enhances the overall look of the paintwork. Slickness - extreme slickness allows the car to stay cleaner between washes plus dirt is easily released from the surface to make the job of regular washing far easier than without a sealant. The sealant we used in this scenario is CarPro Reload - a world renowned product providing a short term (4-6 month) layer of protection similar to what Quartz coatings provide. We apply this in a spray on and buff off technique. Carnauba Wax Carnauba wax is based off the natural Copernicia Prunifera palm. Traditionally a Carnauba Wax provides the best level of shine as a top layer for paintwork and provides the additional benefit that being a paste, it can also aid to hide remaining deep scratches which were unable to be corrected. In this instance we applied a Carnauba Wax paste to the vehicle and after allowing it to cure for one hour we removed the wax using a soft microfibre to avoid inflicting any surface marring to the vehicle. The overall shine of the paintwork was now simply jaw dropping and left the car looking 'wet'. We are regarded as one of the best in the country for the final finish of paintwork and it is all of the careful steps combined into one which leave the end result our customers desire. | |

Exterior Finishing

After completion of the paintwork there were only minor exterior finishing touches to be completed before we could start the interior work. We started by applying a rain repellent to the exterior glass; allowing it to cure before buffing it off and cleaning the glass to a haze and streak free finish. We then applied a long lasting tyre protectant to add a satin sheen and repel dirt and water; and then performed a final check over of the exterior to look for wax residue, polishing dust or other left over traces of the work that had been completed.

After completion of the paintwork there were only minor exterior finishing touches to be completed before we could start the interior work. We started by applying a rain repellent to the exterior glass; allowing it to cure before buffing it off and cleaning the glass to a haze and streak free finish. We then applied a long lasting tyre protectant to add a satin sheen and repel dirt and water; and then performed a final check over of the exterior to look for wax residue, polishing dust or other left over traces of the work that had been completed.

Interior Detailing

Unfortunately in a bit of a hurry we forgot to take photos of our processes with the interior! As in all stage 4 packages the following processes were completed.

Interior Vacuum

All interior surfaces including the boot are vacuumed. We pay attention to the carpets, mats, seats and under the seats. In the Gallardo there is also a lot of Alcantara features on the dashboard and centre console areas which were delicately vacuumed also.

Steering Wheel

The Alcantara steering wheel was looking worse for wear. There were signs of previous oils from the old owner which made the Alcantara look flat and unloved. With our specialist products and techniques we were able to bring back the steering wheel to a near-new finish; some wear remained which would need a replacement to correct - something our customer was not too interested in doing!

Interior Plastics Detailed

Using both pH Neutral interior cleaners and an array of different soft bristle brushes and microfibres we delicately detailed the interior plastics and left the surfaces clean and protected.

+ Interior Glass Cleaned

Unfortunately in a bit of a hurry we forgot to take photos of our processes with the interior! As in all stage 4 packages the following processes were completed.

Interior Vacuum

All interior surfaces including the boot are vacuumed. We pay attention to the carpets, mats, seats and under the seats. In the Gallardo there is also a lot of Alcantara features on the dashboard and centre console areas which were delicately vacuumed also.

Steering Wheel

The Alcantara steering wheel was looking worse for wear. There were signs of previous oils from the old owner which made the Alcantara look flat and unloved. With our specialist products and techniques we were able to bring back the steering wheel to a near-new finish; some wear remained which would need a replacement to correct - something our customer was not too interested in doing!

Interior Plastics Detailed

Using both pH Neutral interior cleaners and an array of different soft bristle brushes and microfibres we delicately detailed the interior plastics and left the surfaces clean and protected.

+ Interior Glass Cleaned

| | Interior Carbon Fiber As a special request we were asked to detail the carbon fiber interior of this vehicle. The door cards are complete carbon fiber as is the centre console areas. Due to our investments we are lucky enough to have a Rupes Mini dual action polisher which made light work of a normally strenuous task on the door cards. We hand polished all of the centre console to avoid excessive dust and risk of staining plastics and after performing a two-stage cut and polish on the interior we followed up with a synthetic sealant and carnauba wax; the same process as the exterior surfaces. It's amazing the clarity we recovered from these surfaces. After repeated interior cleaning from previous owners there was light swirl marks and scratches which were in need of correcting. |